Natural gas is an integral part of how the United States meets its energy needs. The process by which it is removed from the ground is an important part of meeting those needs. This blog post will provide a brief summary of the extraction process utilizing hydraulic fracturing.

Natural Gas- What is Is, and Where it is Found

Natural gas is what is referred to as a fossil fuel- or a source of energy created through the decomposition, and compression of once living material. Over millions of years, this organic material is buried deeper and deeper beneath new earth, and is introduced to higher and higher temperatures. This increase in temperature, compression, and the natural decomposition process causes the organic material to change on a molecular level. The carbon bonds- which originally linked different carbon atoms together are broken down, and this produces thermogenic methane- what most people know as natural gas.

Not surprisingly, natural gas deposits are often found in the vicinity of oil deposits. The deeper one goes, the more natural gas is expected. This is based on the idea that more pressure, and higher temperatures will break more carbon bonds, which create the potential for more natural gas.

Once the natural gas is found, the next step is to remove it safely. Today this is mostly done through the process of hydraulic fracturing-sometimes called “hydro-fracking” or “hydro-fracturing.”

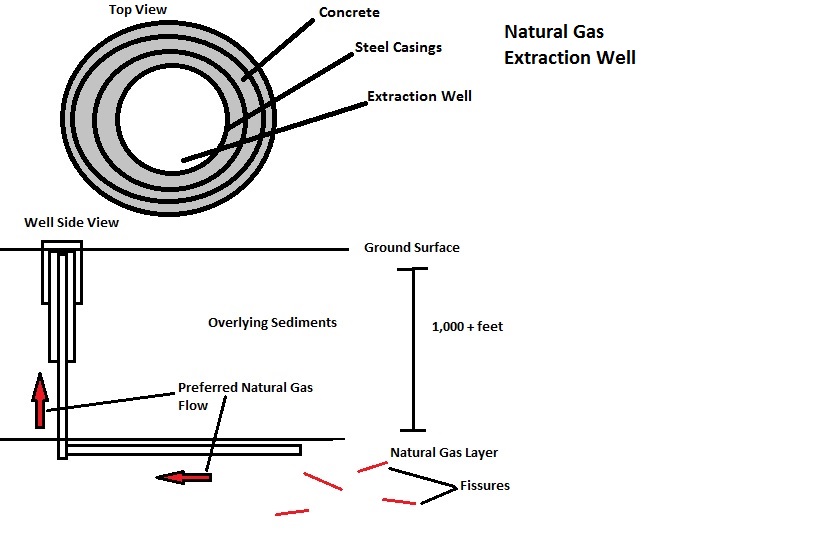

The process of hydraulic fracturing begins with drilling a hole deep into the ground- deep enough to reach the layer of rock that is expected to contain the trapped natural gas. During the vertical drilling, a well is constructed, section by section. The well consists of a steel casing surrounded by a concrete seal. For each section, the casing is smaller and smaller until the smallest diameter steel casing reaches the depth of the natural gas bearing formation- usually shale. The use of progressively smaller steel cases surrounded by concrete is done to try and mitigate contact between the water supply and the fracking material that is used in the second portion of the process.

Once the vertical well is constructed, the drill is turned horizontally and drilled for another few hundred to few thousand feet to reach the target formation. At this point, a highly pressurized mixture of sand, water, and various chemicals are pumped through the well and into the formation. This pressurized material produces cracks or fissures in the rock formation, which provides the natural gas a way to escape from the rock formation. The natural gas then takes the easiest route to the surface, which in this case would be the well.

The Aftermath

Once the natural gas is extracted the whole process is not over. The process utilizes thousands of gallons of water, and the waste water materials produced must be handled in a safe manner. Also the natural gas itself has to be refined and processed for use. Those processes, however will be left for subsequent blog posts.

Resources and More Information

Pennsylvania Department of Environmental Protection “Hydraulic Fracturing Overview” 07/20/2010

Hi! I’ve been following your website for some time now and finally got the bravery to go ahead and

give you a shout out from New Caney Tx! Just wanted to say keep

up the excellent work!